Industry solutions

Our proven expertise in automotive software and hardware development enables the creation of high-performance embedded system products. We assist customers in transforming their concepts into market-ready serial products, adapting to the rapidly evolving automotive industry. In addition, we offer end-to-end hardware and software services for a wide range of applications, including ADAS (Advanced Driver Assistance Systems), Vehicle Connectivity, Telematics, and more.

At DigitalGate, we employ diverse development methodologies tailored to project type, customer requirements, and standards. We complement these with our internal quality management procedures. In the automotive sector, we primarily use two development methodologies: the V Model for validation and testing, and the agile approach, chosen based on project specifications.

We offer complete BSP development services that include infrastructure development, as well as the required modularity for scalability and long-term maintenance. Our BSP solutions are of the highest standards in the industry, customized to customer requirements.

Our BSP Development Services include:

Our team of embedded engineers has a rich experience with various microcontrollers: single processors, multi-processors, as well as digital signal processors. We also specialize in optimizing, testing, and debugging hardware prototypes and shortening the ‘time–to–market‘ for the products we design. Our middleware software brings unified interfaces with scalable and transparent functionalities overcoming problems related to reuse and code portability.

Key Development Areas:

We offer custom embedded solutions by using modern frameworks for domain-specific applications, APIs for integration with other systems and libraries, as well as simulators for quick prototyping, widgets, or display controls. All User Interface development and integration services that we offer are meant to bring color, ease of use, and aesthetical design to the integrated systems. In addition, our solutions are cross-platform and highly flexible, with high-performance capabilities, integrating simple and user-friendly APIs, designed for multilingual support.

Key Development Areas:

Our team of expert engineers can improve performance, reliability as well as efficiency along with the implementation of advanced control algorithms. We do this through the usage of tunable automated optimization methods, and with the development of controller code for embedded systems that are designed to meet the performance requirements of the hardware. In addition, our team is specialized in the development of algorithms that are customized to solve various kinds of tasks.

Our team of embedded engineers offers software solutions that incorporate the basic concepts of automotive cybersecurity.

Internal Vehicle Communications:

Vehicle Connectivity:

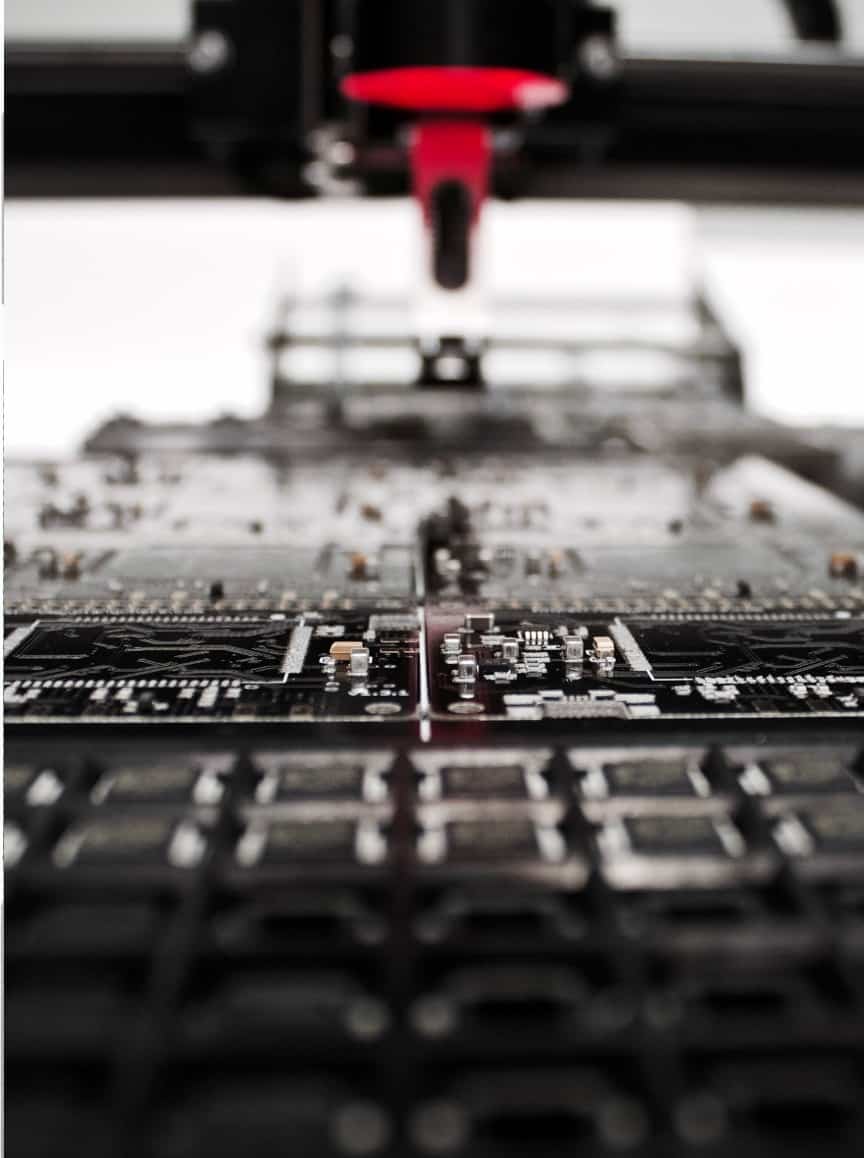

To ensure superior quality in automotive system designs, our team creates simulation environments for circuitry. We ensure electrical, thermal, and mechanical parameters that adhere to application and regulatory limits.

Additionally, our engineers strictly adhere to project specifications, aid in communication with PCB manufacturers, and select suppliers for cost-effective PCB production. Our hardware solutions withstand extreme temperatures climates, from -20°C to 70°C and high humidity.

We provide end-to-end automotive hardware development, encompassing electronic schematic design, layout, and optimization. Throughout the design process, we focus on:

Our team of hardware engineers takes care of all aspects related to PCB schematic design, from the initial system concept up to the actual schematic design. We also offer schematic designs that are optimized and simulated thoroughly.

Key Development Areas:

Our team of engineers offers end-to-end solutions that accelerate the design of the most complex electronics and intelligent systems. By using specialized layout software, our team implements according to the schematic/ the optimized layout for the PCB.

Key Development Areas:

Our team of expert hardware engineers optimizes the design of the PCBs’ by taking care of all aspects regarding component placement, spacing, clearances, thermal relief, and shape restraints. Our team also debugs, inspects, and tests so that the PCB design is fully optimized for serial production.

Key Development Areas:

Compliant with the requirements of ISO 26262 – Functional Safety Standard