Industry solutions

With our proven expertise in medical device software and hardware development, we deliver successful embedded system products. We assist clients in turning their concepts into market-ready products, adapting to rapidly evolving markets. Our services encompass engineering, hardware, and software solutions for the medical electronics industry, covering control, conversion, sensing, processing, storage, display, and information transfer for medical field systems or applications such as defibrillators, ventilators, and laser treatment devices among many others.

We employ various development methodologies based on project type, client needs, and standards, while adhering to our internal quality management procedures. In the medical devices industry, we primarily utilize two development approaches: the waterfall methodology and agile methodology.

We offer complete BSP development services for medical devices that include infrastructure development as well as the required modularity for scalability and long-term maintenance. Our BSP solutions are of the highest standards in the industry, tailored to customer requirements.

Our BSP Development Services Include:

Our team of embedded engineers has a rich experience with various microcontrollers, from single processors to multi-processors and digital signal processors. We specialize in optimizing, testing and debugging hardware prototypes and shorten the “time to market” for the designed products. Our middleware software brings unified interfaces scalable and transparent functionalities overcoming problems related to reuse and code portability.

Key Development Areas:

We offer tailored embedded solutions for medical devices by using modern frameworks for domain specific applications, APIs for integration with other systems and libraries, simulators for quick prototyping, widgets, or display controls. All the User Interface development and integration services that we offer are meant to bring color, ease-of-use and aesthetical design to the integrated systems. Our solutions are cross-platform, with high-performance capabilities, integrating simple and user-friendly APIs, designed for multilingual support and highly flexible.

Key Development Areas:

We offer tailored embedded solutions for medical devices by using modern frameworks for domain specific applications, APIs for integration with other systems and libraries, simulators for quick prototyping, widgets, or display controls. All the User Interface development and integration services that we offer are meant to bring color, ease of usage and aesthetical design to the integrated systems. Our solutions are cross-platform, with high-performance capabilities, integrating simple and user-friendly APIs, designed for multilingual support and highly flexible.

Key Development Areas:

2D image reconstruction:

3D image reconstruction from:

Our security solutions are compliant with ISO 14971 and incorporate the following steps:

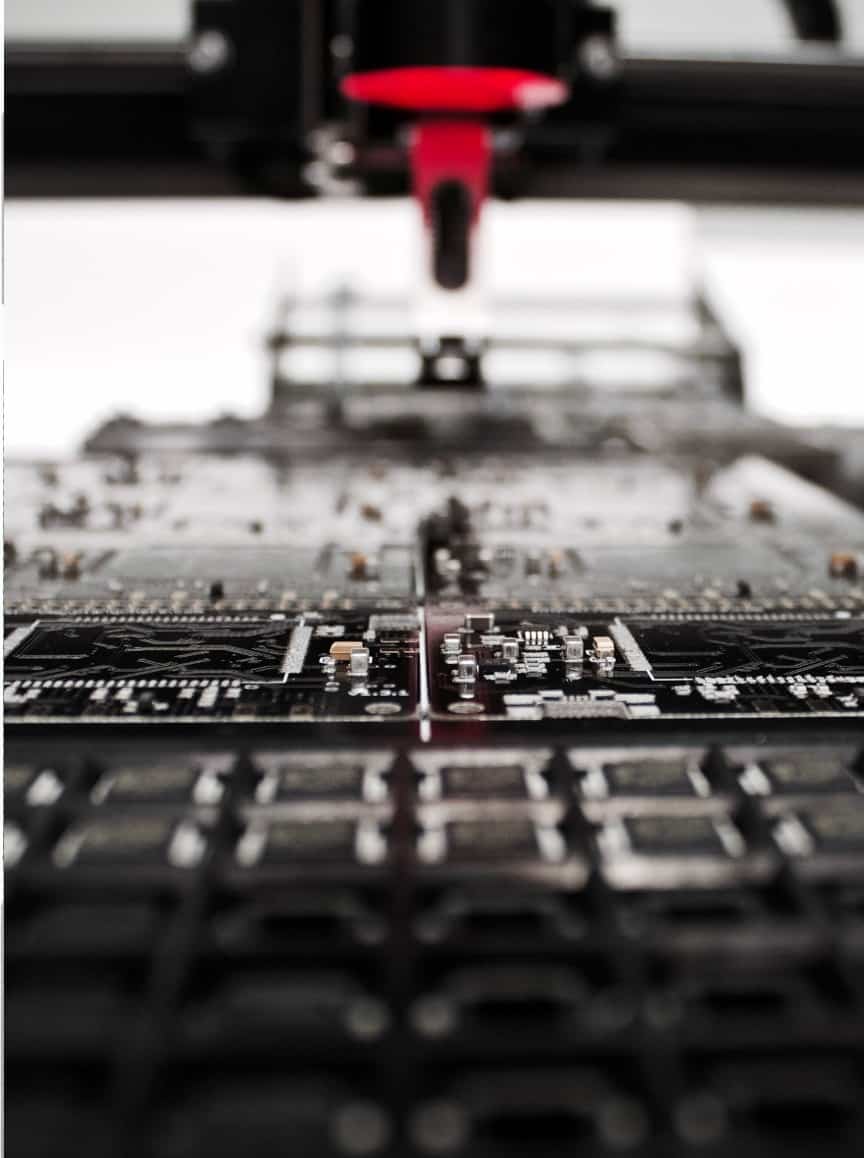

We develop hardware for medical devices from concept to creation. This includes the design of the electronic schematic, layout design, and design optimization. For every step of development process our team ensures that:

To ensure a superior quality of the systems we design, our team develops the necessary environments for simulating the circuits so that the electrical, thermal, and mechanical parameters fall within the limits allowed by the client and legal requirements.

Our engineers also ensure that the circuits are manufactured according to project specifications and provide customers with the necessary assistance in communicating with the printed circuit board manufacturers, choosing the best suppliers that can produce the printed circuit boards according to the specifications of the design and within the budget of the customers.

Our team of hardware engineers takes care of all aspects related to PCB schematic design, from the initial system concept up to the actual schematic design. We offer optimized schematic designs that are optimal and simulated thoroughly.

Key Development Areas:

Our team of engineers offers end-to-end solutions that accelerate the design of the most complex electronics and intelligent systems. By using specialized layout software, our team implements acording to the schematic the optimized layout for the PCB.

Key Development Areas:

Our team of expert hardware engineers optimizes the design of the PCBs’ by taking care of all aspects regarding component placement, spacing, clearances, thermal relief, and shape restraints. Our team of engineers debugs, inspects, and tests so that the PCB design is fully optimized for serial production.

Key Development Areas: