Introduction to Our PCB Philosophy

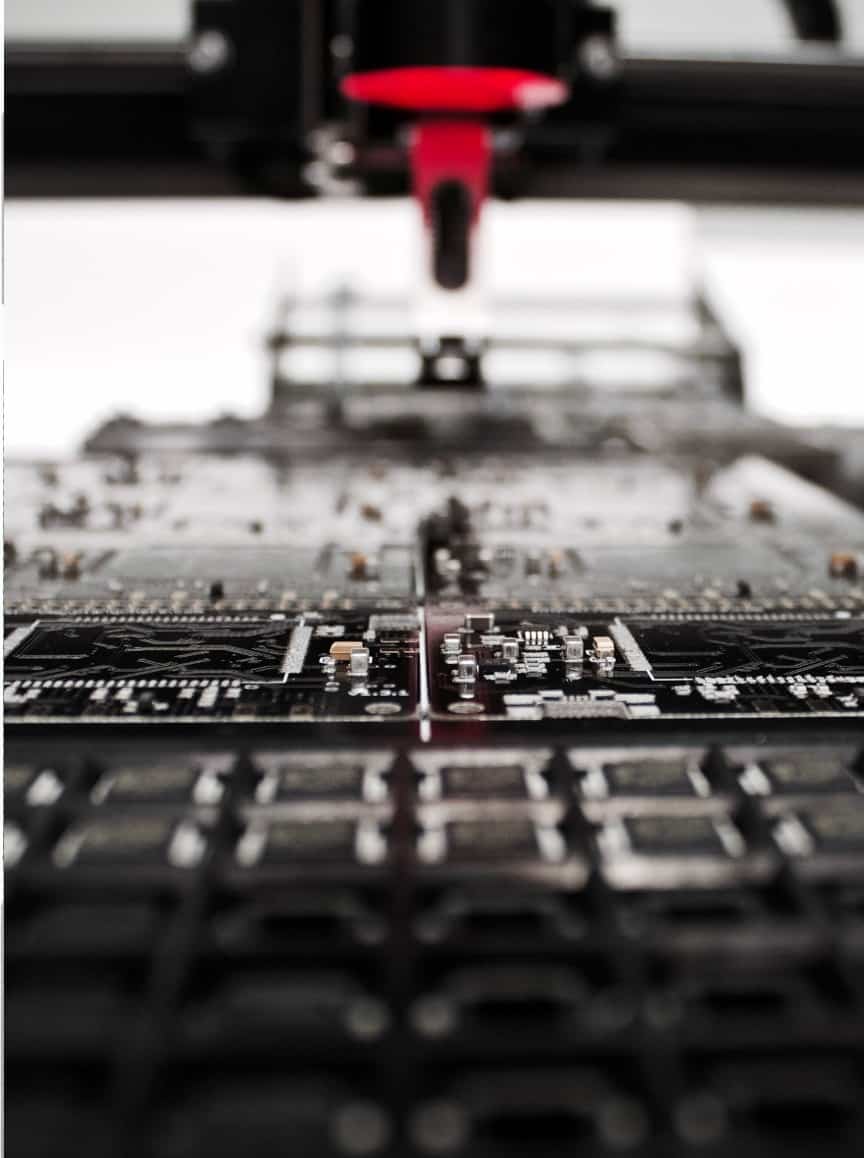

At DigitalGate, our PCB philosophy is rooted in delivering exceptional quality, innovation, and reliability. We believe that effective PCB design and manufacturing are not just about creating functional electronic components but about creating solutions that enhance the performance, durability, and efficiency of your products. Our approach integrates cutting-edge technology, rigorous standards, and a commitment to excellence at every stage of the process.

We produce a large variety of printed circuit boards (PCBs), such as rigid-flex, flexible, double-sided, and multilayer PCBs. Our broad range of skills enables us to manage projects of all sizes and levels of complexity.

Our team produces accurate and effective PCB designs using cutting-edge CAD programs like Altium Designer and Eagle. We can control intricate designs and guarantee excellent results with the help of these technologies.

DFM is a collection of guidelines that concentrates on PCB design for dependable performance and effective manufacturing. By optimising designs to save production costs, minimise errors, and guarantee ease of assembly, we apply DFM.

Fast functional prototype creation is a key component of our rapid prototyping process, which helps us test and improve concepts prior to full-scale manufacturing. Through early identification and resolution of possible problems, this strategy shortens time-to-market.

We use strict quality control procedures, such as functional testing, in-circuit testing, and automated optical inspection (AOI). By taking these precautions, every PCB is guaranteed to perform and depend on high standards.

Indeed, we can manage both small-batch and large-scale manufacturing runs and provide tailored solutions. Because to our adaptable methodology, we can handle a range of project sizes and specifications.

Lead times differ based on the kind of PCB and project complexity. In order to meet your specific demands, we may give anticipated lead times and accelerated services for quick prototyping.

Absolutely, we offer design support to help you all the way through the PCB development process. To guarantee the success of your project, our skilled engineers provide advice on design optimisation, manufactureability, and integration.

We follow global guidelines like RoHS and REACH to guarantee that our PCBs are safe for the environment and comply with legal requirements.

You can get in touch with our sales staff directly or through our website to seek a quote. Give us specifics about your project’s needs, and we’ll be pleased to send you an estimate that’s tailored to your needs.

You can reach our support team by phone, email, or using the website’s contact form if you have any questions or need assistance. We are available to help you with any queries or problems you might encounter.

Choosing DigitalGate for your PCB manufacturing needs means opting for quality, innovation, and reliability. Here’s what sets us apart in the industry:

Advanced Technology: We leverage the latest in PCB manufacturing technology, including automated optical inspection (AOI), laser drilling, and advanced plating techniques. Our state-of-the-art facilities are equipped with cutting-edge machinery that ensures precise, consistent production at every stage.

Rapid Prototyping: Time is of the essence in today’s fast-paced market. We offer rapid prototyping services that allow you to quickly iterate on your designs, reducing time to market and enabling faster innovation cycles. Our prototyping processes are streamlined to deliver high-quality PCBs with minimal lead times, so you can move from concept to production in record time.

High-Quality Standards: Quality is at the core of everything we do. Our PCBs are manufactured in compliance with international standards such as IPC-A-600 and ISO 9001. We adhere to strict quality control protocols, including in-circuit testing (ICT), X-ray inspection, and functional testing, ensuring that every board we produce meets the highest standards of reliability and performance.

Customization and Flexibility: We understand that every project is unique, which is why we offer tailored solutions to meet your specific needs. Whether you require a small batch of prototypes or a large-scale production run, we can adjust our processes to deliver exactly what you need, when you need it.

Expert Support: Our team of experienced engineers and technicians are here to support you at every step of the way. From initial design consultations to post-production support, we provide expert guidance to ensure your project’s success.

Sustainability and Compliance: We are committed to environmentally responsible manufacturing practices. Our processes are designed to minimize waste and energy consumption, and we ensure compliance with environmental regulations such as RoHS and REACH.

By choosing DigitalGate, you’re partnering with a leader in PCB manufacturing who understands the importance of quality, innovation, and customer satisfaction. We are dedicated to helping you bring your electronic products to life, with PCBs that deliver superior performance and reliability.